Key Projects

Patent-Pending Medical Device with Two-Chamber Extrusion Mechanism

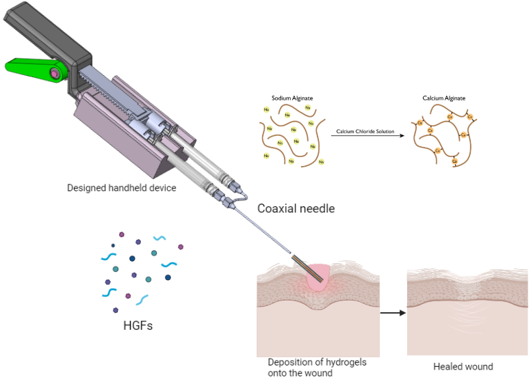

Led the complete design lifecycle of a patent-pending medical device for in-situOn-body Operation wound repair during larynx surgery, featuring a two-chamber extrusion system for controlled medicine delivery and precise dosage through a ratcheting trigger and gear train mechanism.

- Designed initial prototype from concept through detailed engineering

- Developed ratcheting trigger and gear train for controlled, precise medicine extrusion

- Optimized chamber geometry for consistent flow and surgical precision

- Led multiple design iterations based on testing feedback

- Ensured FDAU.S. Food and Drug Administration regulatory compliance and managed patent documentation

- Coordinated cross-functional development team to achieve design goals

Tools Used:

Mechanical Validation Testing

Conducted comprehensive mechanical testing using Universal Testing Machines to validate prototype performance, ensure tolerances, and confirm clinical reliability for surgical applications.

- Performed tension and compression testing for material strength validation

- Executed bending tests to simulate surgical use conditions

- Confirmed clinical performance requirements and documented test results for FDA compliance

Customer Discovery & Market Analysis

Led comprehensive customer discovery initiative including market analysis and user interviews with surgeons to define product requirements and optimize device ergonomics for clinical use.

- Conducted interviews with laryngeal surgeons

- Analyzed competitive landscape and existing solutions

- Identified unmet clinical needs in wound repair

- Optimized device ergonomics for surgical workflows

- Defined product requirements based on user feedback